Vacuum Mixer Homogenizing Emulsifying Machine Body Lotion Vacuum Emulsifier Face Cream Cosmetics Mayonnaise Making Machine

Products Description

Introduce:

Structure:Stainless steel mixing tanks are widely applied in the beverage, food, dairy, chemical and process industries usedas blender tank, buffer tank and storage tank, which cleanable to sanitary standards .1.Capacity :100-20000L 2.Single layer/ double layers/ three layers3.Motor power:0.75-5.5kw4.Materials are all sanitary stainless steel .5.Humanized structure design and easy to operate .6.Transition area of interior wall on tank adopts arc for transition to ensure no dead comer of sanitation .Configuration of tank :1.Quick open manhole .2.Various types of CIP cleaners .3.Fly and insect resistant sanitary breathing cover .4.Adjustable triangular bracket .5.Dismountable materials input pipe assembly .6.Thermometer (According to customer requirements ).7.Ladder (According to customer requirements).8.Paddle blender .9.Liquid level meter and lever controller (According to customer requirements) .10.Eddy-proof board .

Model | Volume(L) | Blending power(kw) | Blending rotation speed(r/min) | Homogenizing power(kw) | Homogenizing rotation speed(r/min) | Heating method |

GYM-200 | 200 | 1.5 | 0~63 | 4.0 | 0~3200 | Steam heating Or Electric heating |

GYM-500 | 500 | 3.0 | 0~63 | 7.5 | 0~3200 | |

GYM-1000 | 1000 | 4.0 | 0~63 | 11 | 0~3200 | |

GYM-1500 | 1500 | 5.5 | 0~63 | 11-15 | 0~3200 | |

GYM-2000 | 2000 | 7.5 | 0~63 | 15-18.5 | 0~3200 | |

GYM-3000 | 3000 | 7.5-11 | 0~63 | 18.5-22 | 0~3200 | |

GYM-5000 | 5000 | 11-15 | 0~63 | 18.5-22 | 0~3200 |

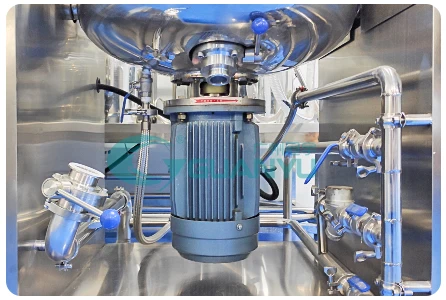

Mixing paddle

Frequency conversion speed regulation 0-62r/min, the shape of the blades will be designed according to your materials.

Homogenizer

Frequency conversion speed regulation 0-3000r/min, homogeneous shearing head high-speed shearing materials, so that the materials are completely broken and mixed!

Oil-water pot

Pre-treatment System Water phase and

oil phase pot to pre-heat and disperse

the raw materials, then transfer them to

main pot to begin production.

oil phase pot to pre-heat and disperse

the raw materials, then transfer them to

main pot to begin production.

Console

The control panel displays and controls the equipment temperature, mixing, homogenization, pressure data, etc. in real

time.

( Optional PLC control )

time.

( Optional PLC control )

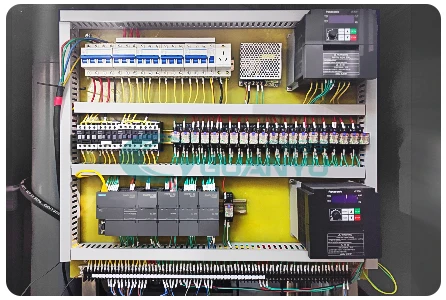

Electric box

Use internationally renowned brand components to ensure the quality of the equipment and longer service life

Service

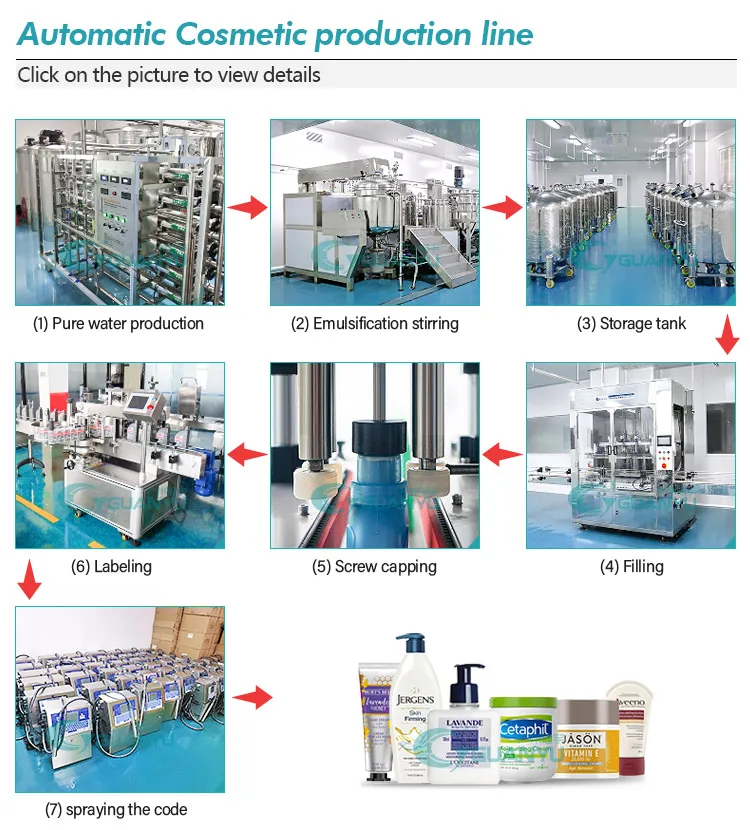

We will design drawings according to your requirements and provide one-stop solutions.

Product configuration

About Us

Successful case process

Certifications

FAQ

Reviews

There are no reviews yet.